Gallery

Photostory: Beneath the Earth

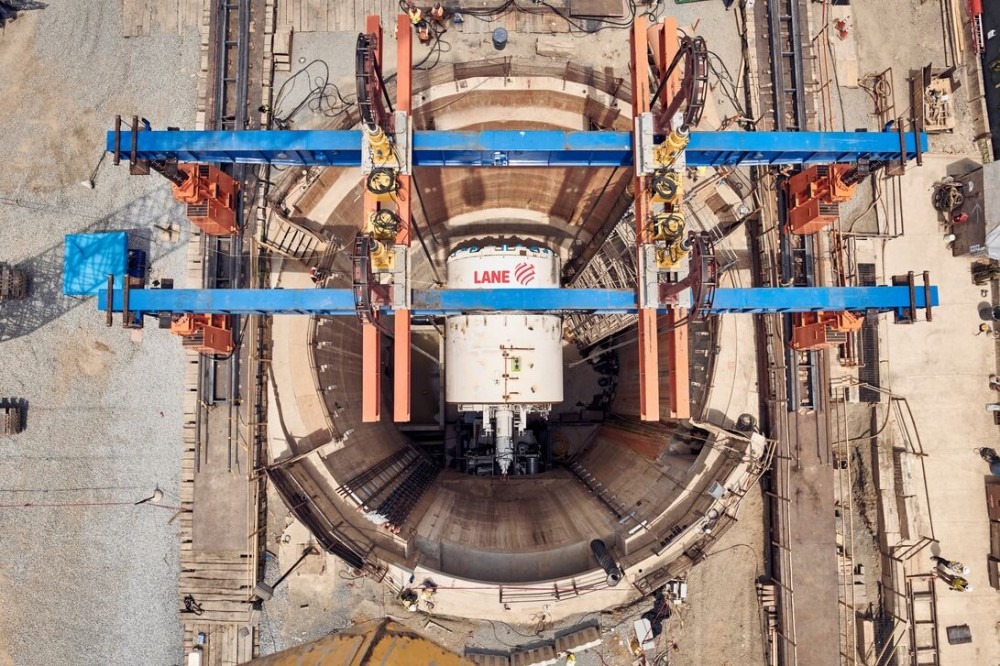

Lane’s Tunneling projects operate in one of the key sectors that influence more efficient and sustainable infrastructure across the country. The company’s reputation in Tunneling has been built from iconic past projects such as the Lake Mead Intake, Anacostia River Tunnel, Portland CSO, San Francisco Underground, and many others. Tunnel Boring Machines, or TBMs, are the massive machines used on these projects that excavate tunnels through all types of earth.

More recently, Lane’s North East Boundary Tunnel in Washington, D.C. used a custom TBM to excavate a 27,000-foot long tunnel under the nation’s capital, while the Three Rivers Protection & Overflow Reduction Tunnel (3RPORT) is nearing completion of a 24,000-foot long tunnel constructed by means of a Slurry TBM in Fort Wayne, Indiana. Lane’s Dugway Storage Tunnel project in Cleveland, Ohio uses a TBM to excavate a 14,800- foot long tunnel with an objective of reducing the level of environmental pollution in Lake Erie.

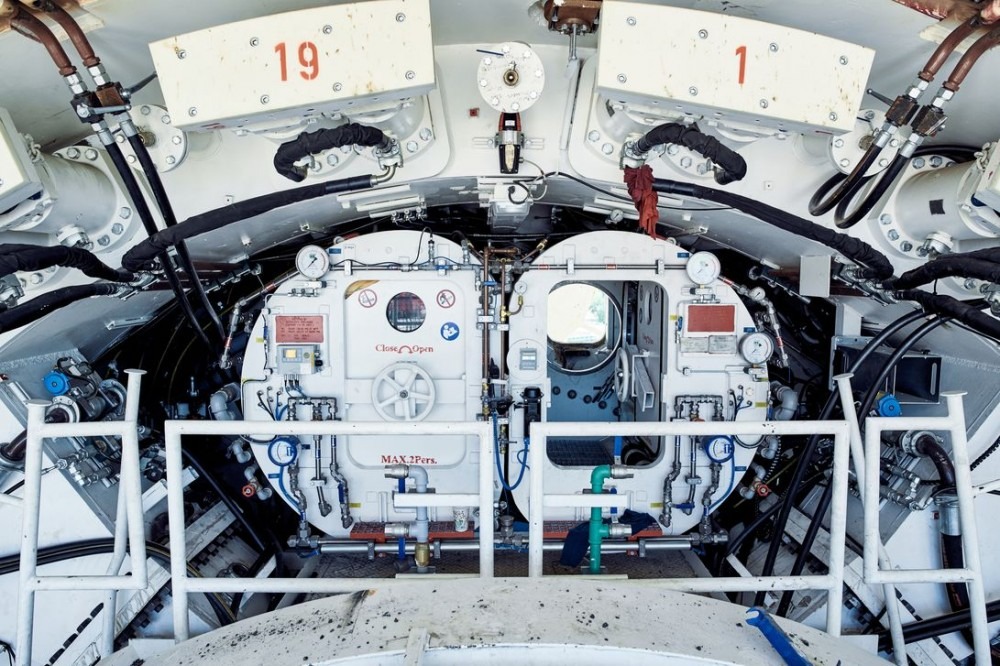

The Seattle Ship Canal project is the latest tunneling project that has been awarded to Lane in King County, Washington. Project teams are currently working on the excavation of a 13,000-foot long tunnel designed to assist the project in keeping more than 75 million gallons of polluted stormwater and sewage out of local waterways each year. The TBM used for the Seattle Ship Canal project is a 70-ton Earth Pressure Balance constructed by Herrenknecht. The process of designing, building testing, and shipping a TBM for a project is a lengthy one. Typically the process from start to finish is 12 to 15 months for a smaller machine, and up to 2 years for a larger, more complex machine. Many considerations come into play during the design of a custom TBM including material procurement, environmental